A predetermined overhead cost rate is an estimated rate used to apply overhead costs to products during the accounting period, calculated before cash flow actual costs are known. One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly. This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process. Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal year. As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner.

Calculating Overhead Rates: Formulas and Examples

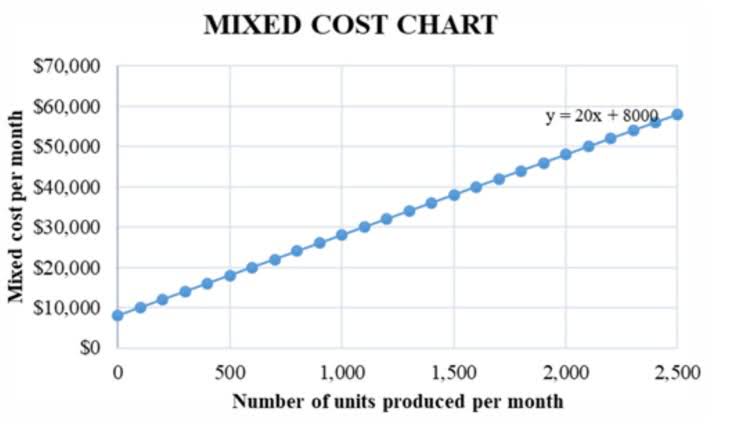

The cost of goods sold consists of direct materials of $3.50 per unit, direct labor of $10 per unit, and manufacturing overhead of $5.00 per unit. With 150,000 units, the direct material cost is $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000. To calculate a predetermined overhead rate, divide the manufacturing overhead cost by the units of allocation. The predetermined overhead rate is a powerful tool for cost management, but it requires careful estimation and periodic review. By understanding its mechanics, businesses can improve financial planning and maintain accurate product costing. If you’re new to managerial accounting, mastering POHR is a crucial step toward AI in Accounting financial proficiency.

- Next, we look at how we correct our records when the actual and our applied (or estimated) overhead do not match (which they almost never match!).

- As a result, there is a high probability that the actual overheads incurred could turn out to be way different than the estimate.

- In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate.

- But before we dive deeper into calculating predetermined overhead, we need to understand the concept of overhead itself.

- The overhead used in the allocation is an estimate due to the timing considerations already discussed.

- This option is best if you’re just starting out and don’t have any historical data to work with.

Multiple or departmental predetermined overhead rates:

- The plantwide overhead rate might not help obtain exact figures, but the estimates are efficient enough for better planning.

- Businesses need to calculate a predetermined overhead rate to estimate the total manufacturing costs that are borne on the production of a single unit of a product.

- We’re a headhunter agency that connects US businesses with elite LATAM professionals who integrate seamlessly as remote team members — aligned to US time zones, cutting overhead by 70%.

- If a job is in work in process and has recorded actual direct labor hours of 600 during an accounting period then the predetermined overhead applied to the job is calculated as follows.

- It enables the company to project their indirect costs more accurately, making the budgeting process more efficient.

Suppose a business uses direct labor hours as the activity base for calculating the pre-determined rate. Now ABC Co. can compare its estimated results with actual results to evaluate how it has performed. However, whether ABC Co. made a profit or loss on the actual job can only be determined if the price of the job is known.

C. Financial Reporting

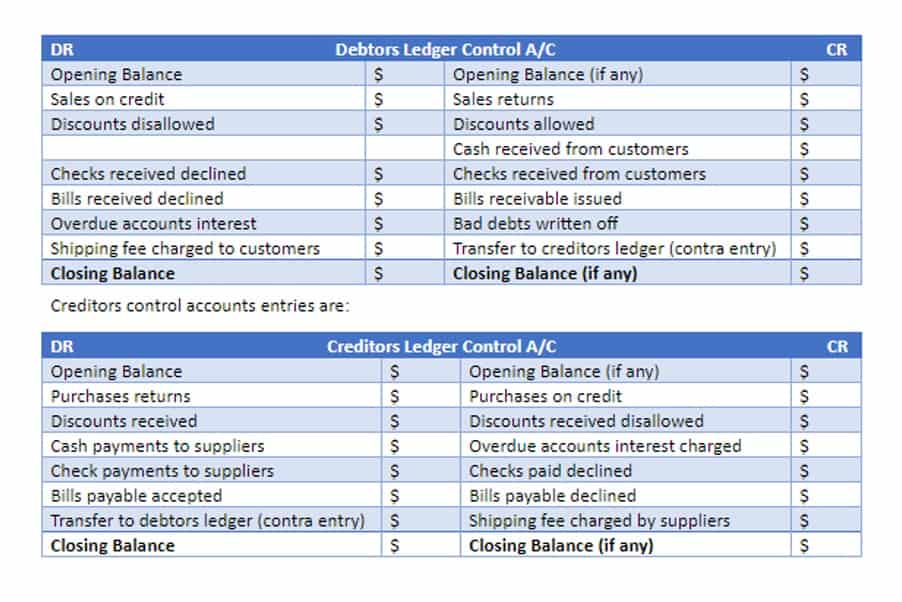

They represent a percentage or rate that is applied to an appropriate cost driver, such as labor hours or machine hours, to assign overhead costs to products. The predetermined overhead rate formula is a critical tool in managerial accounting for determining how much indirect cost a company allocates to its products or services. The primary objective is to accurately determine the cost of producing goods or services by allocating overhead costs based on a particular cost driver. The costs of a product are easy to determine once the product has been produced.

- It’s particularly useful in scenarios where indirect costs are significant and need to be fairly allocated across different products or services.

- A Predetermined Overhead rate shall be used to calculate an estimate on the projects that are yet to commence for overhead costs.

- Renegotiating contracts with vendors may yield savings on supplies or services.

- As the name implies, these overhead rates take into account the entire plant and not a particular segment or department.

- A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base.

- Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products.

By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. Finally, as discussed above, some businesses may calculate their predetermined overhead rates based on historical information. However, these estimates may produce inaccurate results in volatile businesses where predetermined overhead rate historical information cannot be used as a basis to estimate future data. By understanding how to calculate this rate, business owners can better control their overhead costs and make more informed pricing decisions. The Plantwide overhead rate is the overhead rate that companies use to allocate their entire manufacturing overhead costs to their line of products and other cost objects.

- Having an accurate predetermined overhead rate helps companies better understand the full cost of production and set appropriate pricing levels.

- Hence, it is essential to use rates that determine how much of the overhead costs are applied to each unit of production output.

- The costs of a product are easy to determine once the product has been produced.

- If the job in work in process has recorded actual material costs of 4,640 for the accounting period then the predetermined overhead applied to the job is calculated as follows.

- Let’s say we want to calculate the overhead cost of a homemade candle ecommerce business.

Determining Estimated Overhead Cost

Dorothy’s Hat Company computed a predetermined overhead rate based on annual machine hours. The allocation of overhead to the cost of the product is also recognized in a systematic and rational manner. The overhead is then applied to the cost of the product from the manufacturing overhead account.

In this guide, I break down what it is, why it matters, and how businesses use it to allocate costs accurately. The overhead rate helps businesses understand the proportion of indirect costs relative to direct costs. It can be used to allocate overhead when calculating product costs and profits. It means the total number of direct labor hours is taken as the denominator, which is divided by the numerator as the total overhead cost of the company. One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. This comparison can be used to monitor or predict expenses for the next project (or fiscal year).